Product Description:

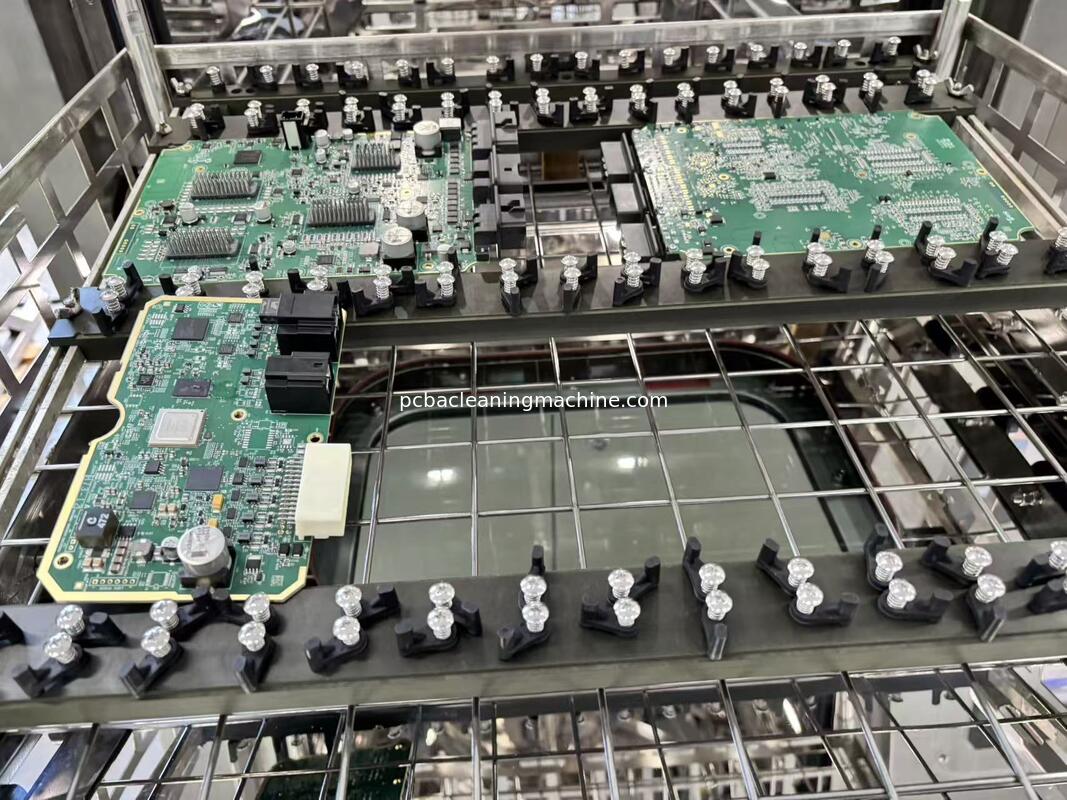

The SME-PC560 PCB Cleaning Machine is an advanced automated cleaning equipment designed to deliver exceptional cleaning performance for printed circuit boards. Engineered with precision and efficiency in mind, this machine offers a seamless and highly effective cleaning solution that is both user-friendly and capable of handling large output volumes.

One of the standout features of the SME-PC560 is its simple operation. The machine is designed to be intuitive and easy to use, requiring minimal training for operators. This simplicity does not come at the expense of performance; instead, it enhances productivity by allowing users to focus on other critical aspects of their production process. The automated cleaning mode integrates cleaning, rinsing, and drying into one compact unit, streamlining the entire PCB cleaning workflow and saving valuable floor space.

In terms of cleaning capacity, the SME-PC560 uses 60CC of cleaning fluid per cycle, ensuring thorough removal of contaminants such as flux residues, dust, and other impurities from the surface of PCBs. This precise amount of cleaning fluid is optimized to achieve the highest cleanliness standards without waste. The machine also features a DI water supply system that operates at a flow rate of 30 to 65 liters per minute and a pressure range of 0.2 to 0.4 kgf/cm². This guarantees effective rinsing after cleaning, removing any residual cleaning agents and ensuring the boards are left spotless.

Another critical aspect of the SME-PC560 is its dry time, which ranges from 10 to 30 minutes depending on the specific requirements of the PCB and the cleaning cycle parameters. This rapid drying capability significantly reduces the overall processing time, enabling faster turnaround for production lines and enhancing throughput. The drying process is integrated into the automatic cleaning mode, making the entire cleaning, rinsing, and drying sequence seamless and convenient.

The SME-PC560 model is designed as a standalone unit; it is not an inline type machine. This means it is ideal for batch processing or integration into various production environments where inline cleaning is not feasible or required. Despite this, the machine maintains a large output capacity, making it suitable for high-volume manufacturing settings. Its robust construction and reliable performance ensure consistent cleaning quality, helping manufacturers maintain high production standards.

The combination of high cleanliness, large output, and simple operation makes the SME-PC560 an excellent choice for companies seeking an effective and efficient PCB cleaning solution. This machine’s automated cleaning mode consolidates three critical processes—cleaning, rinsing, and drying—into one compact and easy-to-manage system, enhancing operational efficiency and reducing labor costs.

In summary, the SME-PC560 PCB Cleaning Machine offers a powerful, automated cleaning solution with a focus on high cleanliness standards and operational simplicity. Its use of 60CC cleaning fluid, efficient DI water supply system (30~65L/min at 0.2~0.4kgf/cm²), and a quick dry time of 10 to 30 minutes make it a reliable and productive asset for any PCB manufacturing or assembly facility. Whether you require batch processing or a standalone cleaning solution, the SME-PC560 is engineered to meet your needs with precision and efficiency.

Features:

- Product Name: PCB Cleaning Machine

- Cleaning Process: Cleaning, Rinsing, Air Drying, Drying

- PCB Dry Temperature: RT~99℃

- Gas Pressure Range: 0.4-0.6 Mpa

- Specification: Maximum PCB Size 330x250mm

- Stencil Size: Maximum L610 x W610 x T100 mm

- In Line Type: No

- Power Supply / Air Supply Included

- Constructed with Total SUS304 Stainless Steel

- Durability: 15 Years Lifespan

Technical Parameters:

| Model |

SME-PC560 |

| Key Selling Points |

The Operation Is Simple, The Cleanliness Is High, And The Output Is Large. |

| Usage |

Remove The Stains On PBCA Using A Chemical Cleaning Agent |

| Cleaning Process |

Cleaning, Rinsing, Air Drying, Drying |

| Machine Type |

Automated Cleaning Equipment |

| Gas Pressure Range |

0.4-0.6Mpa |

| PCB Thickness |

0.5~3.0mm |

| Color |

Original Color Of Stainless Steel |

| Cleaning Fluid |

60CC |

| Stencil Size |

L610*W610*T100mm As Max |

| Vent Size |

Φ76xH50(mm) |

| Application |

1.For small amount, multi-spec PCBA wash. |

Applications:

The Automatic machine equipment for cleaning PCBA, model SME-5600L, is an advanced automated cleaning equipment designed to efficiently remove stains on PCBA using a chemical cleaning agent. Originating from China and certified with CE, this machine ensures high standards of quality and safety. It is ideal for applications requiring high cleanliness, simple operation, and large output, making it a valuable asset in various industrial and manufacturing settings.

This PCB cleaning machine is especially suitable for occasions where there is a need for small amount, multi-spec PCBA wash. Its versatile design allows it to handle different specifications of PCBA, making it perfect for prototype manufacturing, small batch production, and specialized PCB cleaning tasks. The compact machine size of L1300*W1200*H1850(mm) allows it to fit conveniently into most production floors or cleanrooms without occupying excessive space.

In electronics manufacturing plants, the SME-5600L is commonly used during the production process to ensure that PCBs are free from contaminants and residues that could affect performance. It is also applied in repair and refurbishment centers where used PCBs require thorough cleaning before testing or reassembly. The machine’s cleaning process includes cleaning, rinsing, air drying, and drying, which guarantees a thorough cleaning cycle and optimal cleanliness of the PCBA.

The machine uses a precise amount of cleaning fluid, 60CC, to efficiently remove stains while minimizing chemical waste. This makes it environmentally friendly and cost-effective. With a supply ability of 10 sets per month and a delivery time of 4 weeks, it is suitable for businesses needing timely procurement and deployment. The machine is packaged securely in a wooden box to ensure safe delivery.

Payment terms are flexible with T/T accepted, and the minimum order quantity is just 1PCS, making it accessible for both small and large enterprises. Priced at USD 38,000.00, the SME-5600L offers excellent value considering its advanced features and high output capacity. Overall, the SME-5600L is an indispensable piece of equipment for electronics manufacturers aiming to maintain high quality and efficiency in PCB cleaning processes.

Customization:

Introducing the Automatic Machine Equipment for Cleaning PCBA, model SME-5600L, a high-quality PCB cleaning machine proudly made in China. This CE-certified product is designed to meet your specific PCB cleaning needs with precision and efficiency.

With a minimum order quantity of just 1PCS and a competitive price of USD 38,000.00, this machine comes securely packaged in a wooden box to ensure safe delivery. The delivery time is approximately 4 weeks, and payment terms are flexible via T/T. Our supply ability allows us to deliver up to 10 sets every month, ensuring timely availability for your production requirements.

The SME-PC560 model supports a maximum stencil size of L610*W610*T100mm and a PCB size specification of up to 330x250mm. This model operates without an inline type configuration, providing flexibility in various production setups. The machine functions optimally within a gas pressure range of 0.4-0.6Mpa.

Key customization features include the ability to set the DI water rinse time to meet specific ion contamination requirements, ensuring thorough cleaning according to your standards. The diluent liquid heat temperature is adjustable from room temperature up to 99℃, allowing precise control over the cleaning process. Additionally, the DI water supply ranges from 30 to 65 liters per minute at a pressure of 0.2 to 0.4 kgf/cm2, providing efficient and effective rinsing performance.

Choose the SME-5600L PCB Cleaning Machine for reliable, customizable, and efficient cleaning solutions tailored to your PCBA manufacturing needs.

Support and Services:

Our PCB Cleaning Machine is designed to provide efficient and thorough cleaning for printed circuit boards, ensuring optimal performance and reliability. For technical support, please refer to the user manual included with the product, which contains detailed instructions on installation, operation, and maintenance.

If you encounter any issues during setup or operation, ensure that all components are correctly installed and that the machine is connected to the appropriate power source. Regular maintenance, such as cleaning filters and checking fluid levels, is essential to keep the machine functioning properly.

Our technical support team is equipped to assist with troubleshooting, spare parts replacement, and software updates to enhance machine capabilities. We recommend performing routine inspections and following the maintenance schedule outlined in the manual to prevent operational downtime.

For optimal results, use only the recommended cleaning agents and consumables specified for the PCB Cleaning Machine. Using unauthorized materials may damage the equipment or compromise cleaning quality.

We are committed to providing comprehensive service and support to ensure your PCB Cleaning Machine operates efficiently throughout its lifecycle. Please consult the warranty information for details on coverage and service terms.

Packing and Shipping:

Product Packaging: The PCB Cleaning Machine is securely packaged using high-quality, durable materials to ensure protection during transit. Each unit is placed in a custom-fitted foam insert within a sturdy corrugated cardboard box. The packaging includes protective covers for sensitive components, clear instructions for handling, and all necessary accessories and documentation neatly organized. Exterior labels provide handling instructions and product information to facilitate safe and efficient shipping.

Shipping: The PCB Cleaning Machine is shipped via reliable courier services with tracking options available for all orders. We offer various shipping methods to accommodate different delivery timelines and locations. Each shipment is carefully inspected before dispatch to ensure the product arrives in perfect condition. For international orders, appropriate customs documentation is prepared to expedite clearance. Customers receive timely updates on the shipping status until the product is delivered to their doorstep.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!